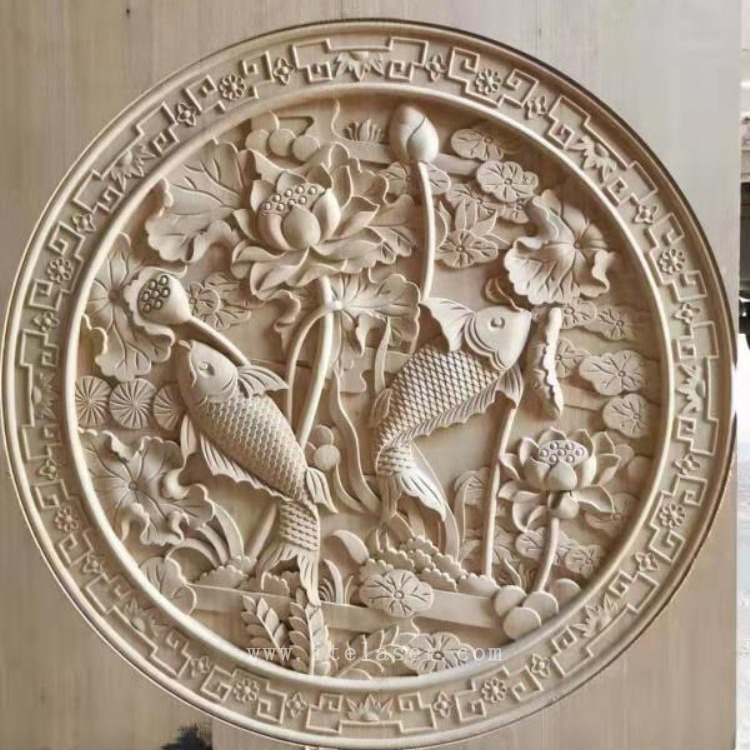

Applications:

ITE-W1325 T8/T12/T16/T20 Disc automatic tool change machining center

Model | ITE1325W |

Working Zone: (X Y Z) | 1300×2500×200mm |

Table Size (W×L) | 1550×2950mm |

Resolution | <0.003mm |

Cutting Accuracy | ±0.03/300mm |

Repositioning Accuracy | ±0.01mm |

Axis Drive System (X Y ) | Rack and pinion drive/ Hiwin rail linear bearing |

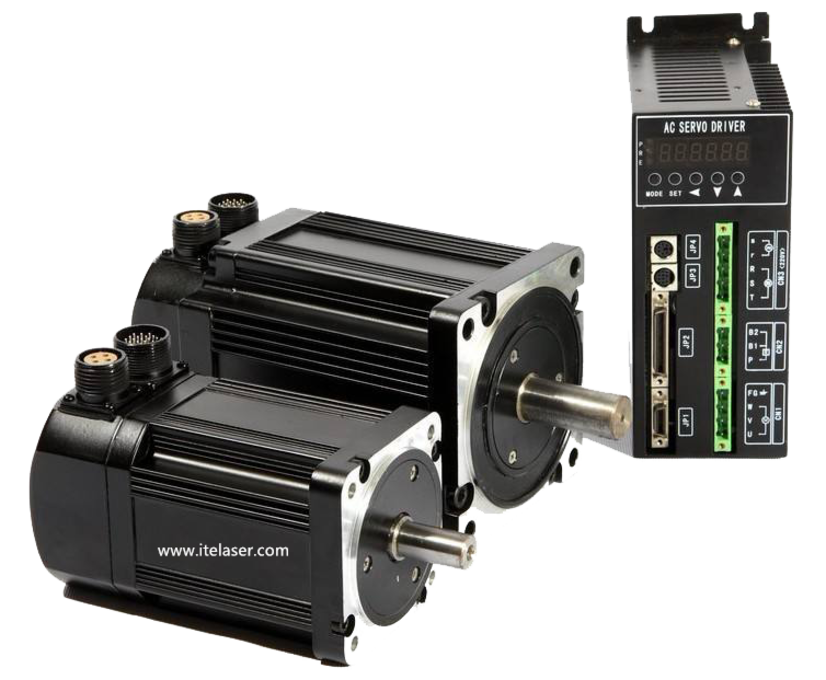

Drive Type | Stepper motor(Servo optional) |

Spindle | 3kw/4.5kw/6kw watercooling spindle (Italy HSD aircooling spindle optional) |

Max. Working speed | 30,000mm/min |

Collets Type | 3.175mm/ 4mm/ 6mm/8mm |

Working Dictate | G Code ,HPGL |

Operational System Software | Type 3/Artcam |

Control System | DSP control system/ Ncstudio/Mach3 |

Interface | PCI/USB |

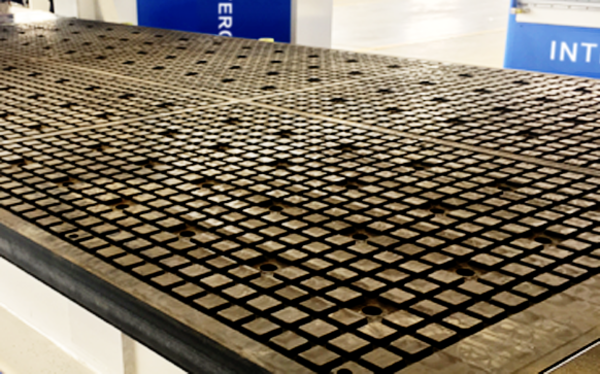

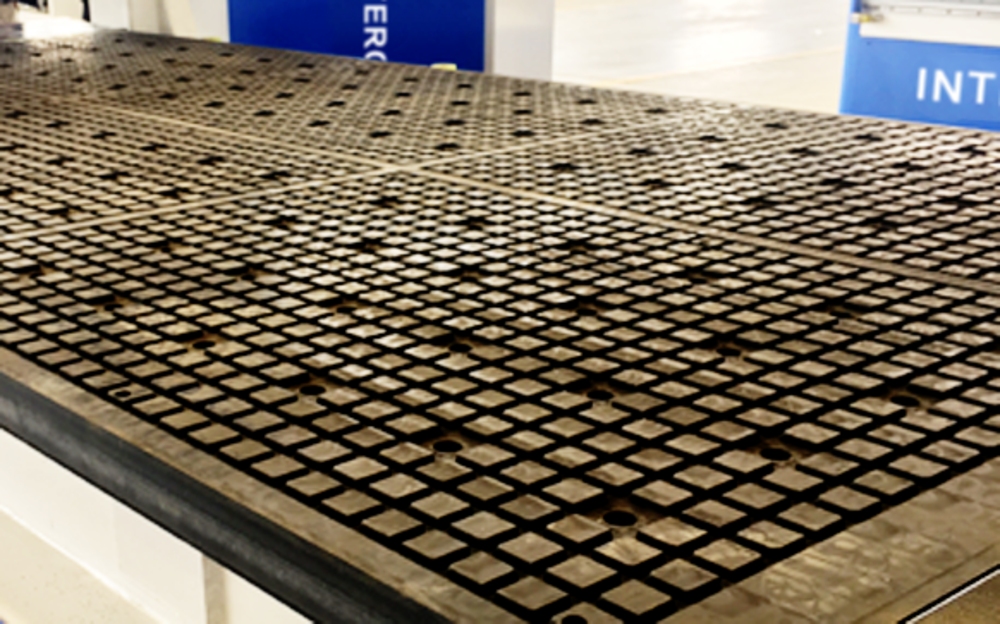

Table surface | T-slot Extrusion, vacuum table |

Voltage | AC220V±10%/50~60Hz |

Standard Work Surface | Aluminum profiles |

Weight | 1550KGS |

Frame | Steel Square Tubes |

Advantages in product details

|

AUTOMATIC LOADING AND UNLOADING Automatic loading and unloading, only one person can carry out the operation, and in conjunction with the edge banding rotary line, one person can complete all operations.

|

|

|

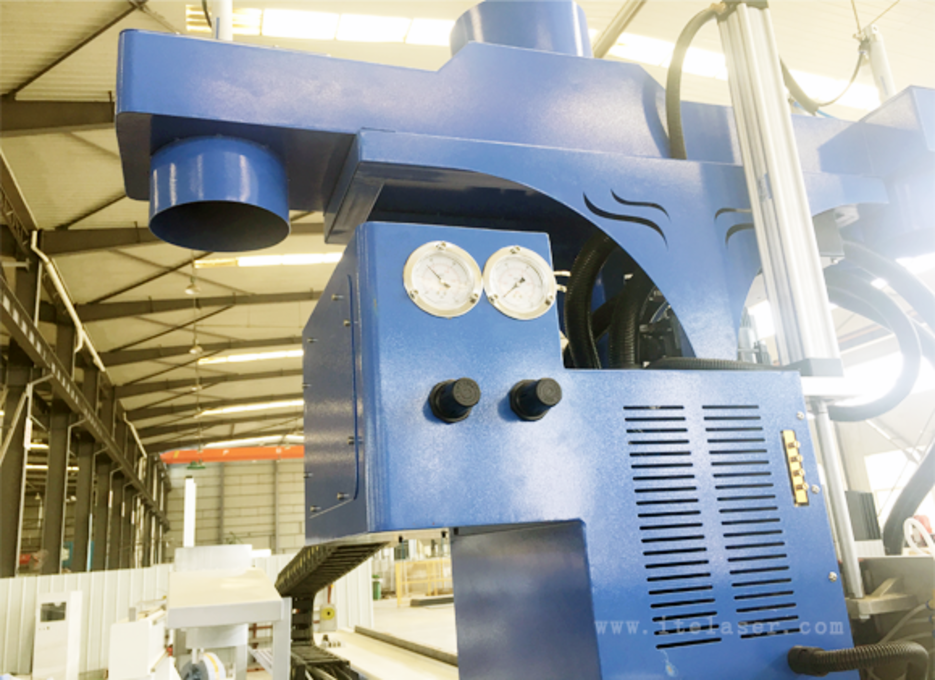

DISC CHANGER |

|

STREAMLINED CONTROL CABINET |

|

|

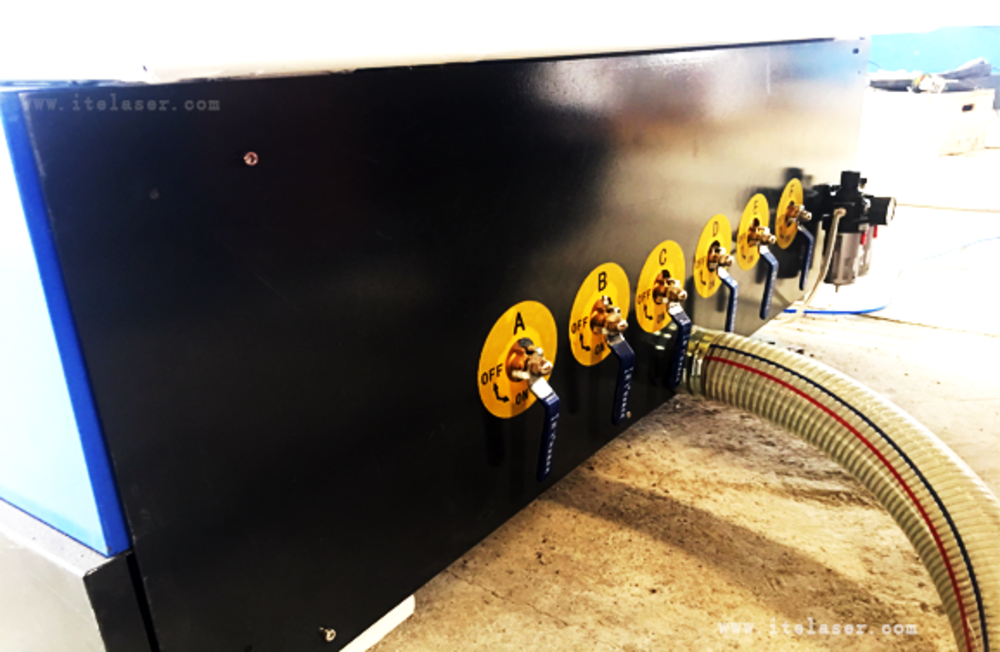

DOUBLE PRESSURE REGULATING DEVICE |

|

JAPAN YASKAWA SERVO MOTOR |

|

|

SIX-ZONE ADSORPTION CONTROL |

|

DOUBLE COUNTERTOP DESIGN |

|